In the realm of modern engineering, the application of artificial intelligence (AI) has extended far beyond science fiction narratives. One of the industries witnessing a remarkable transformation due to AI is pipeline services. As pipelines play a pivotal role in the transportation of oil, gas, and other vital resources, their continuous operation and integrity are of paramount importance. This is where AI’s predictive capabilities are revolutionizing the field of pipeline maintenance.

The Challenge of Pipeline Maintenance

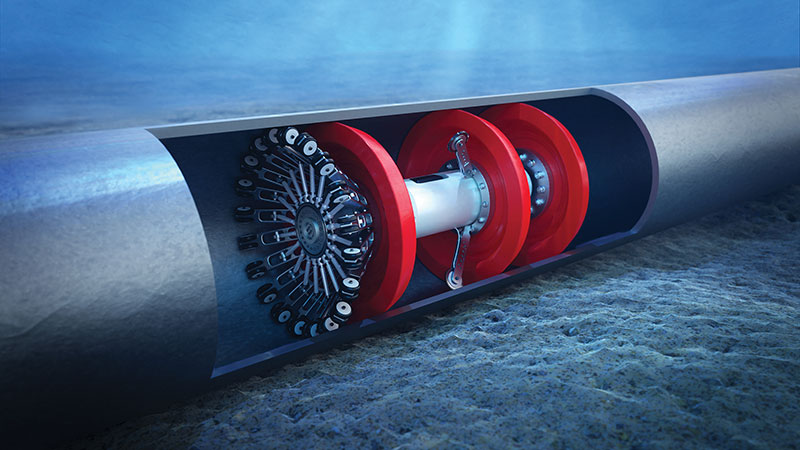

Maintaining the health and safety of pipelines is a complex and ongoing challenge. Pipelines stretch across vast distances, traversing diverse terrains and often operating in extreme conditions. Ensuring their integrity, detecting potential issues, and preventing catastrophic failures demand a comprehensive approach that goes beyond traditional methods of periodic inspections.

Enter Artificial Intelligence

Artificial intelligence, driven by machine learning algorithms, is reshaping the landscape of predictive pipeline maintenance. This technology has the ability to analyze vast amounts of data, detect patterns, and make informed predictions, leading to proactive and targeted maintenance strategies. Let’s delve into the various ways AI is enhancing predictive pipeline maintenance:

Data-driven Decision-making

AI thrives on data, and the more data it processes, the better its predictions become. Sensors, cameras, and other monitoring devices installed along pipelines collect an immense amount of data on factors like temperature, pressure, flow rates, and more. AI algorithms analyze this data in real-time to identify anomalies or deviations from normal conditions. This information enables operators to pinpoint potential issues and take preventive measures before they escalate into major problems.

**Predicting Failures:**

AI-driven predictive maintenance excels in forecasting failures before they occur. By analyzing historical data and comparing it with real-time information, AI models can identify trends that precede pipeline failures. For instance, if a sudden pressure drop is detected, the AI can cross-reference it with historical data to predict the likelihood of a leak developing. Such insights empower operators to schedule maintenance at optimal times, minimizing downtime and reducing the risk of emergencies.

**Condition-based Monitoring:**

Traditional maintenance schedules are often based on average lifespans of equipment and components. However, each pipeline section operates under unique conditions that affect wear and tear. AI enables condition-based monitoring, allowing maintenance interventions to be tailored to the actual state of the pipeline. This prevents unnecessary repairs and extends the useful life of components, optimizing costs.

**Reduced Downtime and Increased Efficiency:**

Predictive maintenance powered by AI optimizes resource allocation. Rather than shutting down an entire pipeline for routine inspections, AI identifies specific areas that require attention. This targeted approach reduces downtime, enhances efficiency, and allows operations to continue uninterrupted whenever possible.

**Challenges and Considerations:**

While AI’s potential in predictive pipeline maintenance is promising, there are challenges that must be addressed. Data quality and integrity are critical; inaccurate or incomplete data can lead to erroneous predictions. Additionally, the implementation of AI systems requires collaboration between data scientists, engineers, and domain experts to ensure the algorithms are trained and validated effectively.

**The Future of Predictive Pipeline Maintenance:**

The integration of AI into pipeline maintenance is not just a technological shift; it’s a paradigm shift in how we approach infrastructure management. As AI technologies continue to advance, we can expect even more sophisticated algorithms, enhanced data analytics, and improved decision support systems. This will result in a more precise and efficient predictive maintenance strategy, reducing costs, minimizing environmental impact, and safeguarding the lives and resources that depend on these pipelines.

In conclusion, artificial intelligence is reshaping the landscape of predictive pipeline maintenance. Its ability to process vast amounts of data, identify patterns, and predict failures in real-time is transforming the way pipelines are managed. This technology not only enhances safety but also improves efficiency, reduces downtime, and lowers operational costs. As AI continues to evolve, its role in ensuring the integrity of pipeline networks will become increasingly vital, safeguarding critical resources and contributing to the sustainability of the oil and gas industry.