Pipeline Integrity Management: A Comprehensive Guide

Introduction

In the complex network of the oil and gas industry, pipelines serve as the lifelines that transport hydrocarbons from production fields to processing facilities and end consumers. Ensuring the integrity of these pipelines is of paramount importance to ensure reliable operations, safety, and environmental protection. This comprehensive guide delves into the world of pipeline integrity management, providing insights into its importance, key components, and strategies for maintaining the reliability of these vital conduits.

The Significance of Pipeline Integrity Management

Pipeline failures can have catastrophic consequences, ranging from environmental disasters to disruptions in energy supply. Pipeline integrity management is a systematic approach designed to prevent such failures by assessing, monitoring, and maintaining the structural and operational integrity of pipelines throughout their lifecycle. By addressing issues before they escalate, pipeline integrity management not only ensures safe operations but also enhances the lifespan of these valuable assets.

Key Components of Pipeline Integrity Management

1. **Risk Assessment and Identification:**

Effective pipeline integrity management begins with a comprehensive risk assessment. This involves identifying potential threats, such as corrosion, third-party damage, and natural hazards. Advanced tools like geographic information systems (GIS) help analyze data to pinpoint vulnerable areas and prioritize resources for mitigation.

2. **Preventive Maintenance:**

Regular preventive maintenance is essential to address issues before they compromise pipeline integrity. Techniques like inline inspection, cathodic protection, and coating assessment play a crucial role in identifying and addressing corrosion, erosion, and other structural concerns.

3. **Monitoring and Inspection:**

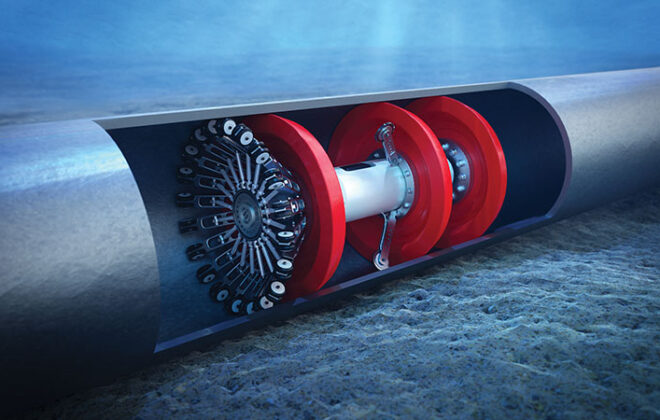

Continuous monitoring is key to identifying anomalies and deviations from normal operating conditions. Advanced technologies like smart pigs (pipeline inspection gauges) and fiber-optic sensors offer real-time insights into the condition of pipelines, helping detect potential issues early on.

4. **Data Analysis and Predictive Analytics:**

The collection of vast amounts of data from inspections and monitoring requires sophisticated analysis. Predictive analytics, driven by artificial intelligence and machine learning, help identify patterns and trends that can predict potential integrity risks.

5. **Emergency Response Planning:**

Despite all preventive measures, unforeseen events can still occur. An effective emergency response plan outlines the steps to be taken in case of a pipeline failure, ensuring swift and coordinated actions to minimize environmental impact and risks to human life.

Strategies for Maintaining Pipeline Integrity

1. **Regular Inspections and Maintenance:**

Consistent inspection schedules, combined with well-defined maintenance procedures, form the backbone of pipeline integrity management. Timely identification of corrosion, cracks, and other defects allows for targeted repairs and replacements, preventing potential failures.

2. **Intelligent Pigging:**

Utilizing intelligent pigs, or pipeline inspection gauges, enables the internal assessment of pipelines for corrosion, wall thickness, and other anomalies. These devices offer a comprehensive view of the pipeline’s condition without the need for excavation.

3. **Cathodic Protection:**

Cathodic protection systems are designed to prevent corrosion by using a controlled electrical current to protect pipelines from deterioration. Routine monitoring and maintenance of these systems are vital to ensuring their effectiveness.

4. **Coating and Corrosion Control:**

Protective coatings play a critical role in preventing corrosion. Regular assessments of coating integrity, along with proper application of anti-corrosion coatings, extend the lifespan of pipelines.

5. **Integrating Technology:**

Embracing advanced technologies such as real-time monitoring systems, predictive analytics, and remote sensing helps proactively address potential issues, optimizing resources and reducing downtime.

Conclusion

Pipeline integrity management is not just a regulatory requirement; it is a commitment to operational excellence, environmental stewardship, and public safety. By implementing a holistic approach that encompasses risk assessment, preventive maintenance, continuous monitoring, and data analysis, oil and gas companies can ensure the reliability and longevity of their pipeline networks. As technology continues to evolve, the future of pipeline integrity management promises even more effective and efficient ways to safeguard these critical conduits and the industries they serve.